Because of their differing designs, and because they are produced from different materials, sealing systems have varying behaviour patterns at increasing operating pressures.

When a hard material is used the danger of damage by compression is reduced. On the other hand, a hard material does not have such good sealing characteristics as a soft material, particularly at low operating pressures.

For the best sealing system, effective at high and low operating pressures, a seal constructed from several types of material with different properties is needed. The ideal would be a solid seal made from several materials, having an increasing hardness and reaching a maximum hardness in the rear section of the seal space, where a gap occurs.

However, it is not practicable to achieve this fully although our designs of seals are constructed on a multi-stage principle in an attempt to approach the ideal.

Seals lose their ability to function because of normal wear to the seal material. This is greatest at the instant of starting and at low speeds, and also through erosion of the seal material when the pressurizing fluid flows over the sealing surface and impinges on an area of deterioration.

The first indication is seen at low pressure when, because of wear, the seal is no longer capable of maintaining the required contact with the sealing surface. At high pressure, because the deformation is greater, sealing may continue to be adequate so long as the pressure is maintained.

The first indication is seen at low pressure when, because of wear, the seal is no longer capable of maintaining the required contact with the sealing surface. At high pressure, because the deformation is greater, sealing may continue to be adequate so long as the pressure is maintained.

The life of a seal cannot be predicted in exact terms because it depends on many factors starting with a suitable choice of seal for the job and correct installation. Wear can then be aggravated by lack of lubrication, shaft irregularities, excessive frictional heat, a seal compound which is too soft, ect. The normal life expectancy of seals will also vary considerably from one application to another as acceptable conditions and even the type of seal recommended differ widely.

If the life of a seal is significantly less than average for a particular application, then it is probable that an unsuitable seal was chosen in the first place and that the operating conditions turned out to be more severe than was expected when the seal was chosen.

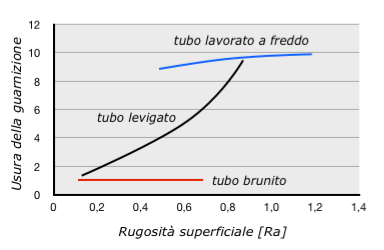

Seal wear is heavily dependent on the finish of the surface against which the seal rubs, this in turn being determined, to a large extent, by the production method.

The figure illustrates this for typical hydraulic cylinders with three different finishes. Seal wear here is graded visually from 0 for no apparent wear, to 10 for a worn out seal. These particular figures were taken after 100.000 cycles of cylinder operation at a working pressure of 250 bar.

A significant factor relative to the above is that with the burnished tube seal wear was largely unaffected by surface finish throughout the range 0.08 μm to 0.7 μm; but rather more so in the case of cold hammered tubes with surface ranging from 0.4 μm to 1.25 μm.