General assembly suggestions

The following are general rules for good installation valid for all types of seals:

- To avoid damaging the sealing lips during installation, housing must have rounded chamfers. Sharp edges and burrs within the installation area of the seal must be removed

- Check presence of lead-in chamfer and absence of sharp and cutting edges

- Lubricate both seal and silding surfaces during assembly with the same fluid as used in the hydraulic system, or with a compatible one

- Adhere to the tolerances and surface finishes stated in this catalogue to make the fitting of the seal easier and to avoid assembly damages

- All parts must be perfectly clean, without metal particles, welding splatter or any kind of defect

- During installation, avoid using pointed or sharp metal tools

- Check the correct orientation of the seal according to the fluid direction

- After assembly, it is advisable to test the cylinder because, during the first cycles, a leakage of a certain quantity of fluid could happen due to the settling of the seals

- To avoid permanent damage of the seals, after completing the cylinder assembly, don’t exceed temperature of 80 °C during operations such as painting, heat curing, etc.

Installation guidelines for rod seals

Usually rod seals can be assembled without using special tools. Rod seals with small diameter need the use of simple assembly tools that can facilitate the assembly. These tools, manufactured conveniently out of metal, should be adapted to the other equipment for the cylinder assembly.

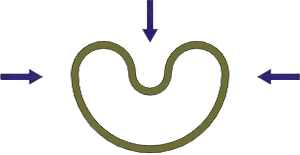

The rod seals can also be easily placed into closed housing grooves deforming them by hand or with a special tool to obtain a ring similar to a kidney shape (see figure).

Installation guidelines for piston seals

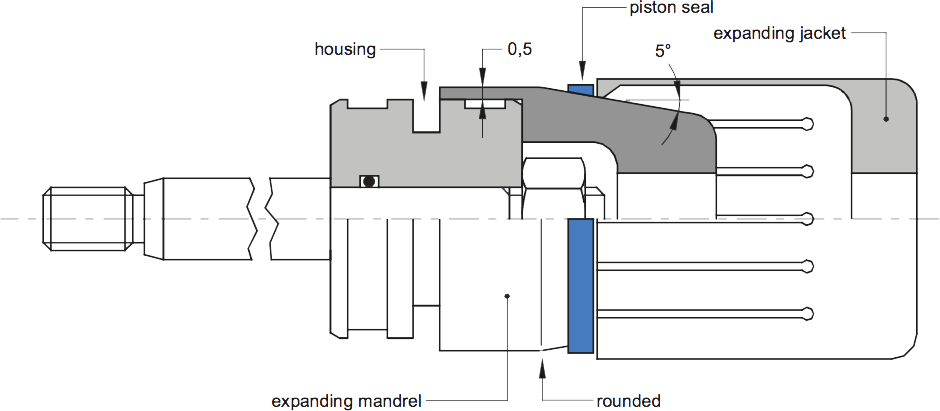

Usually piston seals can be assembled without using special tools. Piston seals with a large radial section in relation to the diameter should be slowly expanded and fitted with simple tools that can facilitate the assembly. These tools, manufactured conveniently out of metal, should be adapted to the other equipment for the cylinder assembly (see figure).

Pre-heating to 50÷60 °C in hydraulic oil is advantageous.