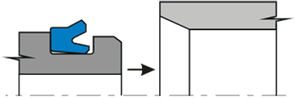

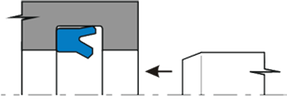

It is very important to ensure rounded lead-in chamfers (see figure) without sharp edges and burrs to avoid damaging the sealing lips during the assembly of the cylinder components.

However it is very difficult, during installation, to damage some resistant materials such as polyurethane, for instance.

In the tables of each item, the values recommended for depth and length of chamfers are shown. A reduction of that values may create assembly problems.