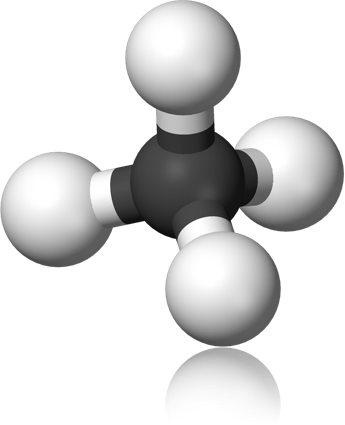

Phenol-Formaldehyde is a high modulus material mainly used in the manufacturing of wear rings. It is a synthetic resin formed from the elimination reaction of phenol with formaldehyde.

Phenol-Formaldehyde is a high modulus material mainly used in the manufacturing of wear rings. It is a synthetic resin formed from the elimination reaction of phenol with formaldehyde.

It is a synthetic resin formed from the elimination reaction of phenol with formaldehyde. It is characterized by a series of outstanding properties: excellent resistance to loads; high tensile strength, extended service life, low friction, wear-resistance, impact resistance and stiffness; “creep” resistance; flame retardant; wide working temperature range from -40°C to +120°C; excellent dimensional stability and accuracy of thickness. For short periods can tolerate temperatures up to +300°C.

At normal temperature phenol is pale yellowish; the color stability of phenol is decreased by the effects of light, air and iron oxides during storage.

Due to its chemical structure it is not suitable for use with foodstuffs.

Datasheet

Description:

- Phenol-Formaldehyde PF

Working temperature :

- -40 ÷ +120 °C

Physical characteristics

- Strength: excellent

- Resilience: excellent

- Resistance to abrasion: excellent

- Resistance to ageing/weathering: good

Fluid chemical resistance

- Resistant to mineral oils, greases, organic solvents, weak acids and alkalis, and saline solutions