Polyurethane is one of the more recently developed elastomers with exceptional strength, tear and abrasion resistance (better than all other rubbers) and retaining excellent flexibility at low temperatures.

Polyurethane is one of the more recently developed elastomers with exceptional strength, tear and abrasion resistance (better than all other rubbers) and retaining excellent flexibility at low temperatures.

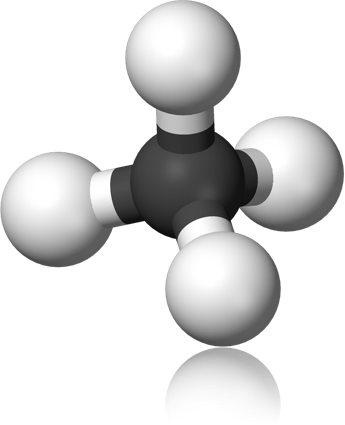

It is an organic material of high molecular weight whose chemical composition is characterized by a large number of urethane groups.

The composition of the material is determined by three components: polyol, diisocyanate and chain extender.

The type and amount of these materials used, and the reaction conditions, are decisive in determining the properties of the resulting polyurethane material.

Resistance is good to petroleum products, hydrocarbons, ozone and weathering. Performance is generally unsatisfactory in contact with aqueous solutions of an acid or alkaline nature, chlorinated hydrocarbons, ketones, hot water, steam or glycol.

Polyurethane rubbers are, therefore, most attractive from the point of view of their mechanical strength rather than chemical or temperature properties. They may be used to advantage, if compatible, under abrasive conditions (particularly for wipers).