Acetal resin with glass fiber is a high modulus material mainly used in the manufacturing of wear rings or anti-extrusion rings (with glass fiber).

Acetal resin with glass fiber is a high modulus material mainly used in the manufacturing of wear rings or anti-extrusion rings (with glass fiber).

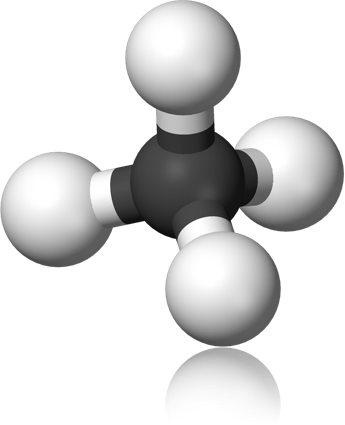

Acetal resins are made by the polymerization of formaldehyde.

The homopolymer offers significantly better mechanical properties than copolymer due to the highly crystalline structure of the acetal homopolymer. They have built up a worldwide reputation for reliability in engineering components.

They are characterized by a series of outstanding properties: high tensile strength, impact resistance and stiffness; good fatigue resistance, unmatched by other plastics; excellent dimensional stability; “creep” resistance; low friction; wide working temperature range, down to very low temperatures.

The low water absorption is especially significant because better dimensional stability in humid conditions is thus guaranteed, even when compared with polyamide.