The velocity between seal and moving surface is a critical factor to be considered on the choice of the seal and it has an important influence on the sealing system performance.

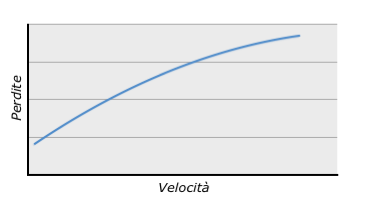

The leakage can be considered as proportional to the square root of the speed (see chapter “Mechanics of sealing”) although it cannot be predicted in exact terms because it depends on so many factors starting with a suitable choice of seal for the job, type of fluid, temperature and surface quality.

Low speed (minore di 0,05 m/s)

In the situation of low speed, there aren’t generally leakage problems although the inconveniences of rapid wear and irregular movement (“stick-slip”) can happen with good chances. In the low speed range, hydraulic pressure generated by motion is not generally sufficient to create a continuous film of fluid and the sealing lip comes into direct contact with the sliding surface giving rise to rapid wear and irregular movement. The “stick-slip” phenomenon, in particular, is a noisy juddering motion caused by a constant repeating of holding and sliding between seal and sliding surface.

In the situation of low speed, there aren’t generally leakage problems although the inconveniences of rapid wear and irregular movement (“stick-slip”) can happen with good chances. In the low speed range, hydraulic pressure generated by motion is not generally sufficient to create a continuous film of fluid and the sealing lip comes into direct contact with the sliding surface giving rise to rapid wear and irregular movement. The “stick-slip” phenomenon, in particular, is a noisy juddering motion caused by a constant repeating of holding and sliding between seal and sliding surface.

The correct choice of seal profile and material (ex. PTFE, with low friction coefficient) can reduce the problem and also improves the fluid and speed control.

Medium speed (from 0,05 to 0,3 m/s)

This is the best situation where there are neither irregular movements, nor excessive losses typical of high speed. In these conditions, the hydraulic pressure generated by motion is able to guarantee a continuous film of fluid between sealing lip and sliding surface ensuring an accurate fluid control and the right lubrication of the seal.

The thickness of the film of fluid, proportional to the square root of the speed, does not generally reach the thicknesses liable to cause undesirable leakages.

Heigh speed (over 0,3 m/s)

As the hydraulic pressure generated by motion increases, the seal is lifted off the sliding surface thus allowing an excessive thickness of fluid to pass. The situation becomes particularly critical when low pressure phases are associated with the high speed. In this case the seal is exclusively subjected to assembly deformation and, under such conditions, high modulus materials show their superiority by ensuring a high loading even in the absence of pressure.