The system temperature is a critical factor to be considered on the choice of materials and has an important influence on the extent of losses.

The system temperature is a critical factor to be considered on the choice of materials and has an important influence on the extent of losses.

As a consequence of friction, the temperature on the sealing lips is generally higher than the system temperature, although it cannot be predicted in exact terms because it depends on many factors starting with the material, profile of the seal, type of fluid and surface quality.

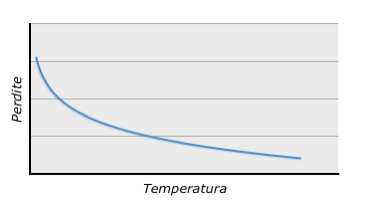

Since the fluid viscosity is inversely proportional to temperature, the leakage can be considered as proportional to the square root of the inverse of temperature (see chapter “Mechanics of sealing”):

perdita ∼ √(1/T)

Low temperature

When viscosity of the fluid grows, hardness of the sealing material increases and the seal loses elasticity thus allowing an excessive thickness of fluid to pass.

Medium temperature

This is the best situation where the fluid has suitable viscosity to prevent losses through sufficient lubrication and the shape variations of the seal due to thermal expansion and variations in hardness don’t decisively influence sealing system performance.

High temperature

The sealing material becomes more elasticised, the volume of the seal increases and the viscosity of the fluid decreases thus reducing losses. However, at the same time, the insufficient lubrication increases the wear and the risk of irregular movements.