Despite begin a simple task, the installation of seals requires particular attention. In fact, careless assembly not only shortens the working life of components but also undermines the efficiency of the whole system. First of all, it is important to make sure that seal type and dimensioning are exactly the same as those envisaged by designers; this can easily be done with the help of the tables contained in almost any technical catalogue. In fact, a ring that is slightly smaller or larger than the ideal ring cannot ensure proper functioning: too small a ring in static seal clearly entails considerable fluid leakage, whereas a seal whose diameter is larger than seat cannot ensure proper sealing as it would press against components during tightening.

Size is a key factor also in dynamic sealing because too small an external diameter promotes leakages while too large a seal can guarantee sealing but it also exerts a significant resistance as it presses against sliding surfaces; since the force needed to over come this obstacle adds to the force of the load, the actual pressure is thus higher than the level envisaged.

For these reasons, it is important to follow the advice and rules for assembly provided by manufacturers. What follow is a general list of recommendations that apply to any seal:

- Make sure that all metal parts have neither sharp edges or burrs nor unlevelled holes and threads.

- Make sure that the seals have neither flaws nor manufacturing residues (pitting, scratches, blisters, etc.)

- Make sure that there are no encrustations, dirt, welding waste, etc.; clean every part carefully.

- Lubricate seals and sliding parts with the same fluid as the system.

- Make sure lip seals are oriented correctly.

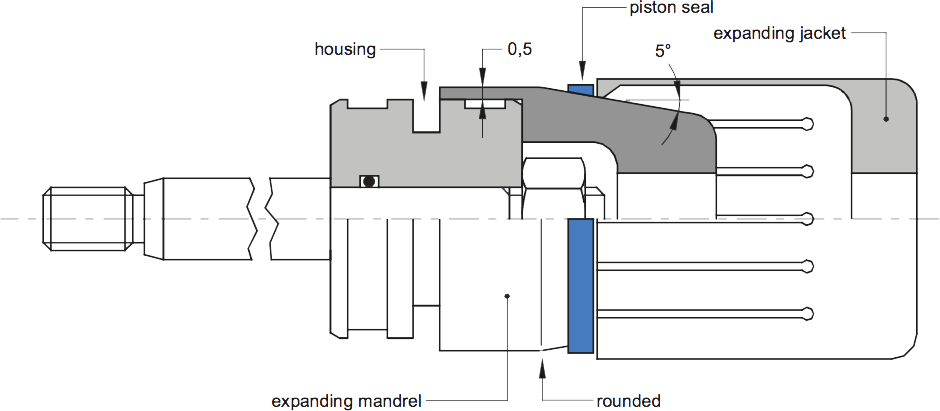

- Do not use pointed tools (cutters, screwdrivers, etc.) in order to arrange the seal into the piston seat. Place a thread cone next to the metal part and use a plastic pusher instead (see Figure 1).

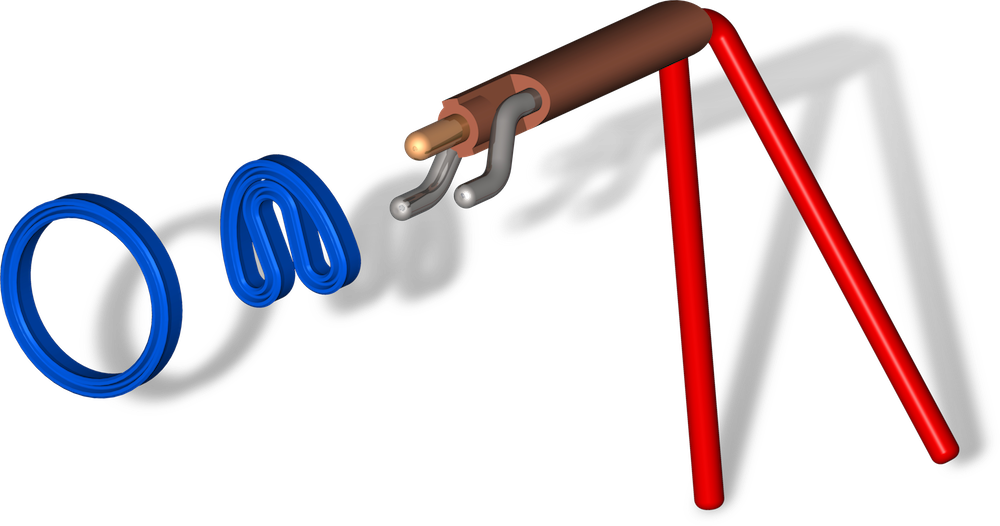

- Rings for rod (head) seal and rod wipers must be placed in the seat after undergoing deformation. In this regard it may be useful a tool as the Seal Twister (see Figure 2).

Figure 1