Installation damage

Damage to an O-ring during installation can occur when:

- There are sharp corners on mating metal over which the O-ring must pass during assembly

- Insufficient lead-in chamfer

- Blind grooves in multi-port valves

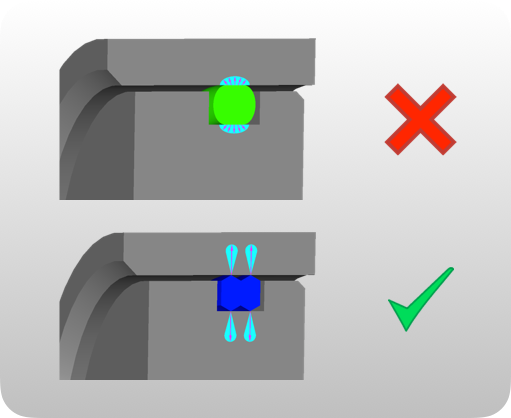

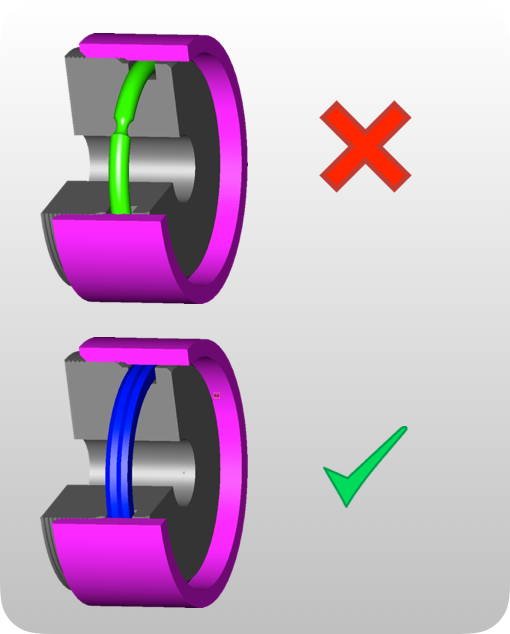

- O-ring twisted/pinched during installation

- O-ring not properly lubricated before installation

- O-ring dirty upon installation

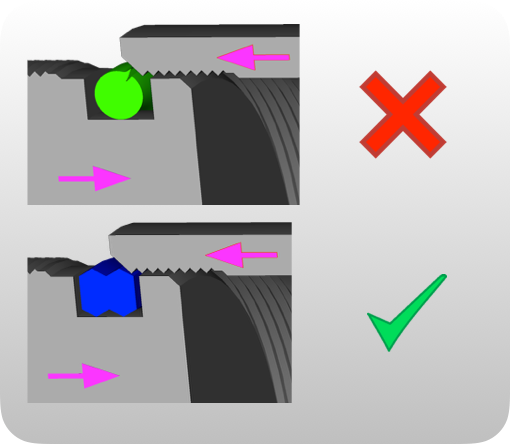

Extrusion resistance

Extrusion and nibbling of the O-ring is a primary cause of seal failure in dynamic applications such as Hydraulic Rod and Piston seals. This form of failure may also be found from time to time in static applications subject to high pressure pulsing which causes the clearance gap of the mating flanges to open and close, trapping the O-ring between the mating surfaces.

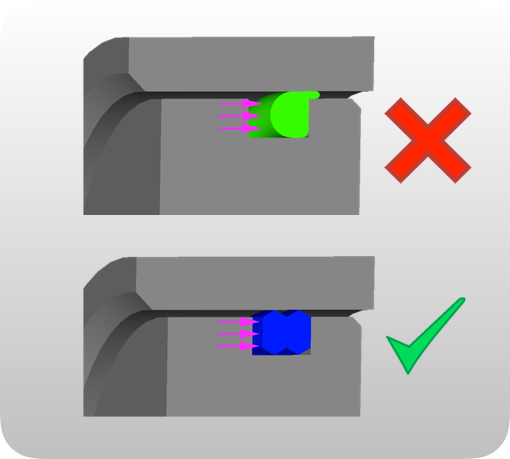

Spiral failure

Spiral failure of an O-ring is often found on long stroke hydraulic piston seals and to a lesser degree on rod seals. This type of O-ring failure is caused when the seal becomes “hung-up’’ at one point on its diameter (against the cylinder wall) and slides and rolls at the same time. The resultant twisting of the O-ring as the sealed device is cycled finally causes the seal to develop a series of deep spiral cuts (usually at a 45° angle) on the surface of the seal.

Sealing capability

The trimmed sealing lips of OP are sharp-edged and can therefore ensure an high dynamic and static sealing effect.